The People

We are a small group of people that have worked for over 20 years to develop the concept of using the power of sound waves, from the field of Acoustics, to

TREAT CONTAMINATED WATER AND PRODUCE CLEAN WATER.

We finally developed, proved and filed four patents that will make that happen. These technologies represent enormous potential for life and the planet in how water is processed, recovered and used. These technologies will also simplify the apparatus and subsequently reduce the costs for energy, production and operation.OVER 8 BILLION PEOPLE NEED MORE WATER, CHEAPER, SIMPLER AND ANYWHERE.

We have the experience to follow the conventional path to exploit these technologies. However, the potential of the technologies is so great that to benefit the most people in the least time, requires more than we few can provide. MORE ENTITIES MUST BE INVOLVED; therefore, we choose to spend our time working in a manner that will permit us to cooperate with third parties, allow access to the technologies, develop viable systems and evolve the best path to put those results to use in as many applications as possible.WITHIN THIS SITE, THE STRUCTURE OF THAT VISION IS DESCRIBED. It is meant to enable the viewer to envision what and where there could be an interjection into the process of making a real difference for the benefit of many. The work to realize all of the potential is immense and will require many people and funds and time but properly implemented the results will come quickly. Read on and contact us with your interest.

The Acoustic Technology Eco Water Recovery

The use of acoustics (SOUND WAVES) in water, referred to generally as “ultrasonics”, has been used for manufacturing processes since the 1960’s. Sound waves, though extremely powerful on liquids, had never been able to be used effectively to process the waste effluent from any operations because the high rate of flowing water dissipates sound waves making them ineffective. New technology developments, resulting in multiple patent filings, now make it possible to USE THAT POWER ON FLOWING WATER.

Processes to EVISCERATE MICROORGANISMS, RECOVER VALUABLE ELEMENTS, REMOVE DISSOLVED SOLIDS, REUSE PROCESS WATER, PRODUCE HYDROGEN and many more are now possible simpler and cheaper than current methods in use today . Those innovations were the result of a dedicated group of individuals with process development and manufacturing experience going back over 40 years.

The Innovations

|

In the process of recovering and producing water, acoustics produces incredible forces such as:

Through sound waves acting on flowing water and other liquids to reduce or replace conventional methods for water recovery such as:

|

top

The Revolutionary Results

One significant feature of sound waves is to generate intense power to disassociate compounds into constituent parts; eviscerate microorganisms entirely; breakdown materials into dissolved solids; emulsify mixtures and more solely by their action or as catalyst to an existing process.

Another significant feature is to allow direct extraction of dissolved solids from a contaminated liquid as it is flowing resulting in a clean water permeate and a concentrated waste effluent, or brine. Further processing can even facilitate achieving zero liquid discharge from brine effluent.

Those two features are embodied in two unique apparatus know as Solids Disassociation Apparatus and Solids Separation Apparatus developed and described in multiple patent disclosures pertaining to sound waves in liquids and other processes. The SDA and SSA equipments are key factors in the processing and recovery of seawater, process water, HYDROGEN production, water mining and many other processes ultimately viable toward achieving ZERO LIQUID DISCHARGE (ZLD) of waste water.

top

The Technology Sharing

Imagine eliminating membrane filtration and high temperature methods with smaller units lower in initial, energy, installation and maintenance costs. But, the scope of potential good from these technologies is so vast that it needs to be available for others to explore and develop processes. Thus, a means was created to be able to share use of these technologies and still insure the innovations have a path to get into daily use and achieve sustainability.

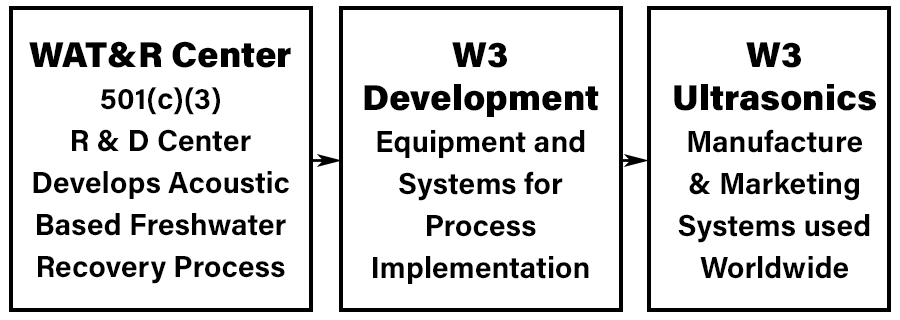

These companies represent the NEXT GENERATION of ECO USE AND RECOVERY OF WATER and are structured to work independently, yet interactively, developing the PROCESS, APPARATUS and PRODUCTION of commercially viable water eco-treatment systems for uses worldwide.

The diagram below shows the three independent companies, their missions and their interdependency. Each is a legally separate entity enabling interaction with third parties without compromise to any other company. All three companies can access necessary technology rights individually to perform their function and insure the operating system for a specific process is freely available to address the need.

top

The Companies

WATER ADVANCED TECHNOLOGY & RESEARCH (WAT&R) CENTER

is a 501(C)(3) NON-PROFIT EXCLUSIVELY FOCUSED ON DEVELOPING PROCESSES to address water use, recovery, reuse and production to freshwater and more using sound waves as the primary active force replacing existing methods but also in synergy with other existing technologies for the best improved process for the application.

As a non-profit, WAT&R CENTER can more freely share access to these new technologies with users, academia, individuals and other third party resources to create the most effective processes for the myriad of applications now able to be resolved with acoustic technology.

W3 DEVELOPMENT LLC

is focused on the research and DEVELOPMENT OF THE COROLLARY EQUIPMENT AND SYSTEMS necessary to implement the processes developed by WAT&R and other sources.Guiding criteria for apparatus development are SIMPLICITY OF CONSTRUCTION AND SERVICE, COST EFFECTIVE UTILIZATION, LINEAR SCALEABLITY, STATE OF THE ART OPERATION and CONTROL and SUPPLY CHAIN OPTIMIZATION. Production of the system and distribution to the point of need is then an actionable option available to a third party(s) to implement.

W3 ULTRASONICS LLC

is focused on PRODUCING AND DISTRIBUTING THE EQUIPMENT AND SYSTEMS to use acoustic technology most effectively and efficiently for eco-friendly processing, recovery and distribution of freshwater for any application.W3 Ultrasonics LLC is an established manufacturer of ultrasonic cleaning and processing equipment with experience going back over 40 years in the field. W3 Ultrasonics, and with domestic and international partners, produces commercially viable operating systems for distribution domestically and worldwide.

W3 Ultrasonics will supply the SDA and SSA core operating units into new automatic water processing machines regardless of system manufacturer.

top

The Parts Cleaning Continues

W3 ULTRASONICS LLC

Continues to be fully involved in ULTRASONIC BASED CLEANING applications and manufacture of operating systems for industrial processing and production, as it has for many years.However, in addition, are now able to evaluate the water stream from initial process use to process water recovery utilizing acoustics as the primary mover to accomplish the process “AT THE SOURCE”.

top